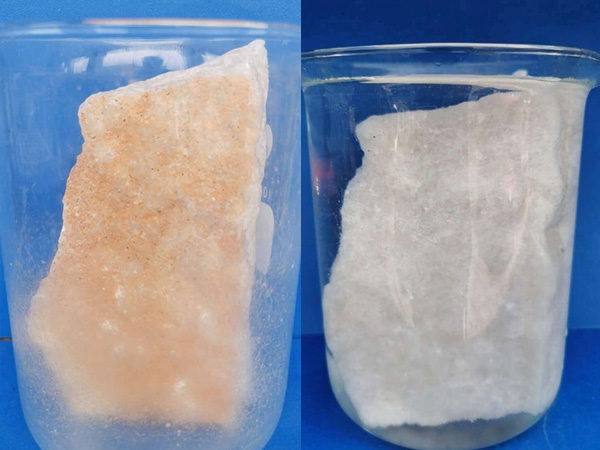

The difference between quartz stone washing agent and pickling method for cleaning stones

Quartz stone washing agent is a special agent for the surface cleaning of quartz stone and ore, which is formulated by Henan Shijie Environmental Protection Technology for minerals in different regions of quartz and non-metallic ores. Can completely replace HCI. H2SO4, subverting the traditional pickling.

Stone washing agent cleaning is to use the complexation or chelation of complexing agents to various scale-forming metal ions to form soluble complexes for cleaning; this product is an oxidant, a catalyst, a coupling agent, and a bleaching agent. Compound agent of various elements such as salt and edible acid. It has a good coupling effect on the oxides in the minerals, and has no side effects on the ore body itself, human body and crops.

Traditional pickling is wet pickling, which uses various acids. Such as sulfuric acid, oxalic acid, etc. Wet crushing is used for crushing before pickling, and some of them are crushed by mechanical methods such as hammer crushing, so that the crushed materials contain a large amount of mechanical iron.

Mechanical iron and quartz sand react slowly in water, and generally after several days, mechanical iron will be oxidized to trivalent iron and turn red and yellow. If the acid is soaked, the iron oxidation rate is faster when exposed to the air.

Quartz sand is widely used in water treatment. During the pickling process, the surface of natural quartz sand ore generally has a layer of molten iron to form a film. This is compared to some fine industries that have strict requirements on iron content. , When using quartz sand in production, it has to go through a secondary cleaning process.

The quartz stone washing agent can remove rust, yellow spots and stains on the surface of quartz ore. It is specially used for cleaning after large-scale mining of quartz stone ore, improving the whiteness and purity of the ore, and restoring the color, texture and vision of the rough stone. The effect is to greatly improve the quality and qualified utilization rate of quartz ore, and greatly improve the economic benefits of ore mining.