【Shi Jie Wang】Provide you with better quartz stone rust remover and yellow peel cleaning agent!

【Shi Jie Wang】The purpose of producing quartz stone rust remover products is to provide a cleaning agent for cleaning quartz ore and its preparation method, so as to solve the problems encountered in the rust removal and purification technology of quartz stone.

【Shi Jie Wang】The use of the quartz stone rust remover can be scrubbed by rod friction or mechanical scrubbing.

- Mechanical scrubbing

For mechanical scrubbing, it is generally believed that the factors affecting the scrubbing effect are mainly from the structural characteristics and configuration of the scrubbing machine, followed by technological factors, including scrubbing time and scrubbing concentration.

The research shows that the scrubbing concentration of sand ore is the best when the concentration is between 50% and 60%. Too large or too small concentration will reduce the erasing effect of impurity minerals, and to a certain extent, it will increase the difficulty of purifying quartz sand; In principle, the scrubbing time is based on the preliminary product quality requirements, and should not be too long, because too long time will increase equipment wear, increase energy consumption, and increase the cost of beneficiation and purification.

- stick friction scrub

After the rod friction scrubbing – desliming – magnetic separation – flotation – acid leaching process, high-purity quartz with a silica content of more than 99.99% is obtained. Quartz beneficiation and purification methods and technological processes are generally determined by the following points:

1.The occurrence state of impurity minerals in the original sand;

2.The beneficiation cost of the purification process;

3.Industrial use of fine sand products.

For the refined sand quartz for general industrial use, a simpler process should be selected as much as possible to reduce the purification cost. It is recommended to use the scrubbing-desliming-magnetic separation process, which can meet the general quality requirements.

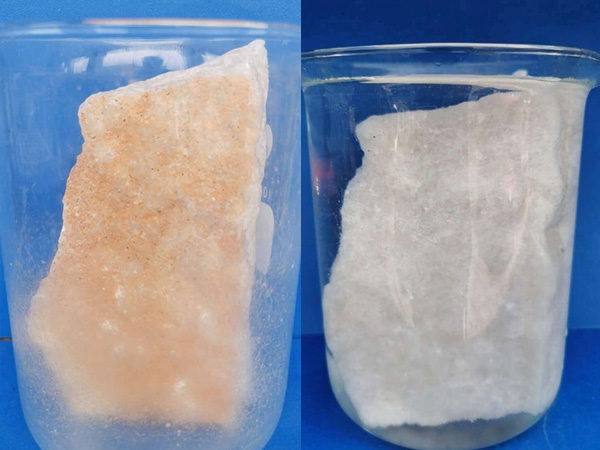

Quartz stone remover does not damage quartz ore. Soaking can remove ore dirt without purchasing special cleaning equipment, which can reduce the cost of use. After cleaning, the surface of quartz ore is white and bright, which is economical and simple to use, safer than traditional strong acid cleaning, and has no discomfort.

With the further improvement of environmental protection and efficiency requirements, the environmental protection and convenient cleaning methods and multi-functional and low-toxic cleaning products will be greatly enhanced, while industrial cleaning tends to standardize professional branding services.

Instruction: Before use, the user can determine the reasonable dosage (the total amount of A and B) according to the surface condition of the ore, the ambient temperature and the cleaning speed. It is recommended to use the ratio of quartz stone rust remover (total A, B): water = 115-30: 3. Preparation method: Put the rust remover into the water according to the proportion, and use the air pump to send the gas into the medicine tank to make it fully dissolved.

Note: The ambient temperature should not be lower than 10 ℃; after opening the package, pay attention to moisture-proof.