Quartz sand purification process technology greatly improves the quality and utilization rate of quartz ore

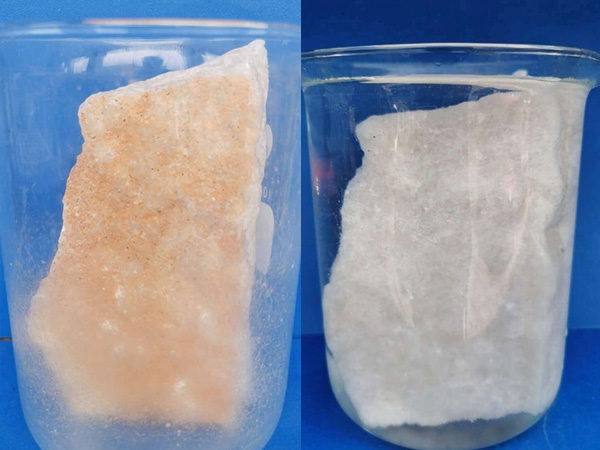

Quartz sand purification process can reasonably eliminate the deep rust, macula and dirt of quartz ore. The technology is used to clean up many quartz mines after excavation, improve the whiteness and purity of the ore, correct the original color of the ore, greatly improve the quality and utilization rate of quartz ore, and further improve the economic benefits of the ore.

Three main elements of chemical reaction in quartz sand purification process:

1, the temperature of water in 0-100 degrees above can be used.

2, the higher the water temperature, the faster the reaction speed, the lower the water temperature, the slower the reaction speed, the low temperature demand patience waiting.

3, the higher the concentration, the faster the reaction speed, the lower the speed is slow.

The quartz sand purification process uses the solvent to dissolve the dirt. If the composition of the pollutants is known, it is very useful to choose a specific solvent. It has a strong ability to dissolve oil or oil. It is generally faster to remove oil stains with solvent than to remove oil stains with lye. Its defect is that organic solvent volatilizes easily to form environmental effects.

Biochemical cleaning is mainly a method for biological contaminants. People have discovered the corrosion and pollution effect of microorganisms on stone materials for a long time. The useful eradication method is to select targeted biochemical cleaning agents for killing, dissolving, differentiation and stripping.

Quartz sand purification process is oxidant, catalyst, osmotic agent, coupling agent, bleach, salt, edible acid, ETA a variety of elements of the compound agent. It has a good coupling effect on oxides in mineral deposits, but has no side effect on ore bodies, human bodies and crops.